the labORATORYTop-level equipment

At the heart of our laboratory is a commitment to quality, precision, and efficiency. We work with the highest quality equipment from carefully selected partners.

Dental componentsDESS®

DESS offers one of the broadest selections of components compatible with various implant systems on the market, covering dozens of different implant connections.

Why do we use DESS dental solutions?

We feature DESS Dental Smart Solutions dental products in our range because we believe in the power of uncompromising quality, broader freedom of choice, and smart solutions. DESS is a globally recognized manufacturer of precision prosthetic components, offering 100% compatible solutions for more than 32 implant systems based on the “Pure Switch” philosophy.

Visit website: www.dessdental.com

Key Features and Advantages-

DESS "Pure Switch" philosophy means their components are designed to be 100% compatible with the original manufacturers' products. This gives us and our partners (dentists and laboratories) great flexibility and freedom of choice, allowing for seamless integration with existing workflows.

-

DESS products are manufactured according to strict quality standards, using materials such as Grade V ELI titanium and other high-quality materials sourced from European suppliers.

Their extensive experience in manufacturing precision mechanical components ensures that every abutment, titanium base (Ti-Base), or other component fits the implant with exceptional accuracy. This is critical for the long-term success of implant work and patient safety.

-

DESS offers a lifetime guarantee on its products, which provides added assurance to us, dental practitioners, and patients alike. The warranty also covers the implants on which DESS products have been used. This underscores their confidence in the durability and quality of their products.

-

DESS is focused on supporting digital dentistry, offering CAD/CAM libraries, intraoral scan bodies, and pre-milled blanks. This allows us to support both traditional and advanced digital workflows.

Special technology like SelectGrip®️ (sandblasting treatment) on titanium bases increases retention for cement-retained restorations by up to 500%.

-

Although DESS products offer premium quality and compatibility, they are often more competitively priced than original manufacturer components, thereby providing excellent value and keeping the cost of dental services at a more reasonable level.

3D printing solutionsStratasys

Stratasys 3D printing solutions aim to accelerate production times, improve patient care, and offer significant time and cost savings. Their solutions integrate seamlessly with existing digital workflows.

Why do we use Stratasys 3D printers?

At our dental laboratory, we are committed to quality, precision, and efficiency to provide you and your patients with the best possible dental solutions. This is why we have integrated cutting-edge printers from Stratasys, the world's leading provider of 3D printing solutions, into our daily workflow.

Stratasys' PolyJet technology and their printers specifically designed for dentistry, such as the J5 DentaJet, offer several advantages that make our work processes faster, more accurate, and more flexible.

The use of Stratasys printers in our lab means: higher quality, greater flexibility, faster service, and maximum patient satisfaction.

Visit website: www.stratasys.com

Stratasys 3d printing solutions-

Stratasys primarily uses PolyJet (inkjet-like multi-material printing) and P3 DLP (Programmable Photo Polymerization) technologies.

J5 DentaJet and J3 DentaJet (PolyJet technology):

These are multi-material 3D printers specifically designed for dentistry.

They can simultaneously print various dental products and applications on the same build tray.

The J3 DentaJet is often presented as a cost-effective, entry-level PolyJet printer for small to medium-sized labs, capable of printing mixed trays containing, for example, implant models, surgical guides, and gum models with exceptional accuracy.

The J5 DentaJet is a more powerful system that can use up to five photopolymer materials concurrently.

Origin®️ One Dental (P3 DLP technology):

It is designed for high-throughput, consistent quality, and accuracy in small-batch manufacturing.

Uses an open material infrastructure and is ideal for flow production.

-

Stratasys printers support a wide range of dental applications:

Models (implant, orthodontic, removable, crown, and bridge models)

Surgical guides

Removable dentures (including full-color and monolithic dentures with TrueDent material)

Gum models (or Gingiva masks)

Orthodontic appliances (e.g., clear aligners)

RPD (Removable Partial Dentures) frameworks

Patient-specific anatomical models for improved surgical planning

-

A specialized portfolio of biocompatible dental resins is used (e.g., VeroDent, VeroDentPlus, VeroMagentaV, VeroDent PureWhite), offering high accuracy and durability.

The TrueDent material is also highlighted, which allows for the printing of full-color monolithic dentures that do not require post-print assembly.

-

The workflow is simplified by GrabCAD Print software, which is specifically designed to streamline the 3D printing process on Stratasys printers.

Stratasys emphasizes that their solutions provide dental labs with the opportunity to optimize resources, achieve greater accuracy and quality, and shorten turnaround times.

Key Features and Advantages-

Stratasys printers ensure exceptional accuracy. This is critical for producing diagnostic models, surgical guides, and prosthetics, guaranteeing a perfect fit every time and minimizing the need for post-processing.

-

Stratasys' technology allows us to simultaneously print parts from different materials and color shades in one printing cycle. For example, we can print at the same time:

Rigid, precise models (for crowns, bridges, implants)

Flexible gingiva masks (soft tissue)

Biocompatible transparent surgical guides

This saves time and reduces workflow complexity, enabling us to create more realistic and complete models for implants and prosthetics.

-

We use Stratasys-approved biocompatible dental materials (such as VeroGlaze™️ and MED-series resins) that meet the highest medical standards. This ensures patient safety and material reliability.

-

The industrial volume and speed of Stratasys printers allow us to rapidly produce large quantities of models and appliances. This translates into shorter turnaround times and the ability to serve you better and faster.

Dental milling machinesVHF

VHF is a German brand that has specialized in milling and grinding solutions for the dental sector since 1986. The equipment, which is 100% developed and produced in Germany, offers precision, automation, and durability to dental clinics and laboratories.

Why do we use VHF milling machines?

By choosing VHF, we are selecting the best technology for our laboratory to create perfect-fitting and long-lasting dental restorations for you and your patients. This pinnacle of German engineering ensures that every crown, bridge, and implant-supported work is fabricated with exceptional precision and maximum efficiency.

Visit website: www.vhf.com

Key Features and Advantages-

VHF equipment is renowned for its industrial quality and supreme precision. The minimal deviation in repeatability (often just a few microns) ensures that every restoration fits perfectly on the first try, reducing the need for post-processing and offering the patient a more comfortable experience.

-

The diversity of work in our lab demands flexibility. VHF solutions support a broad spectrum of dental materials, including:

Zirconia

Glass ceramics

Composites

PMMA

Titanium and cobalt-chrome (CoCr)

This allows us to offer a wide range of indications and choose the most suitable material for every patient.

-

VHF mills are characterized by an open system architecture. This means they are compatible with most common CAD/CAM software (e.g., exocad, 3Shape), allowing us to maintain a smooth digital workflow from scanning to milling. The intuitive DENTALCAM software simplifies the operator's work, ensuring fast and flawless production.

-

VHF machines are designed with maximum productivity in mind. Thanks to powerful spindles and automatic tool changers, we can shorten job completion times. Some models also offer an automatic changeover between wet grinding and dry milling (e.g., on R5 models), further optimizing the work processes.

-

All VHF equipment is 100% developed and manufactured in Germany. This ensures long-term durability, minimal maintenance costs, and consistently high quality, which is vital for the continuous and uninterrupted production in our laboratory.

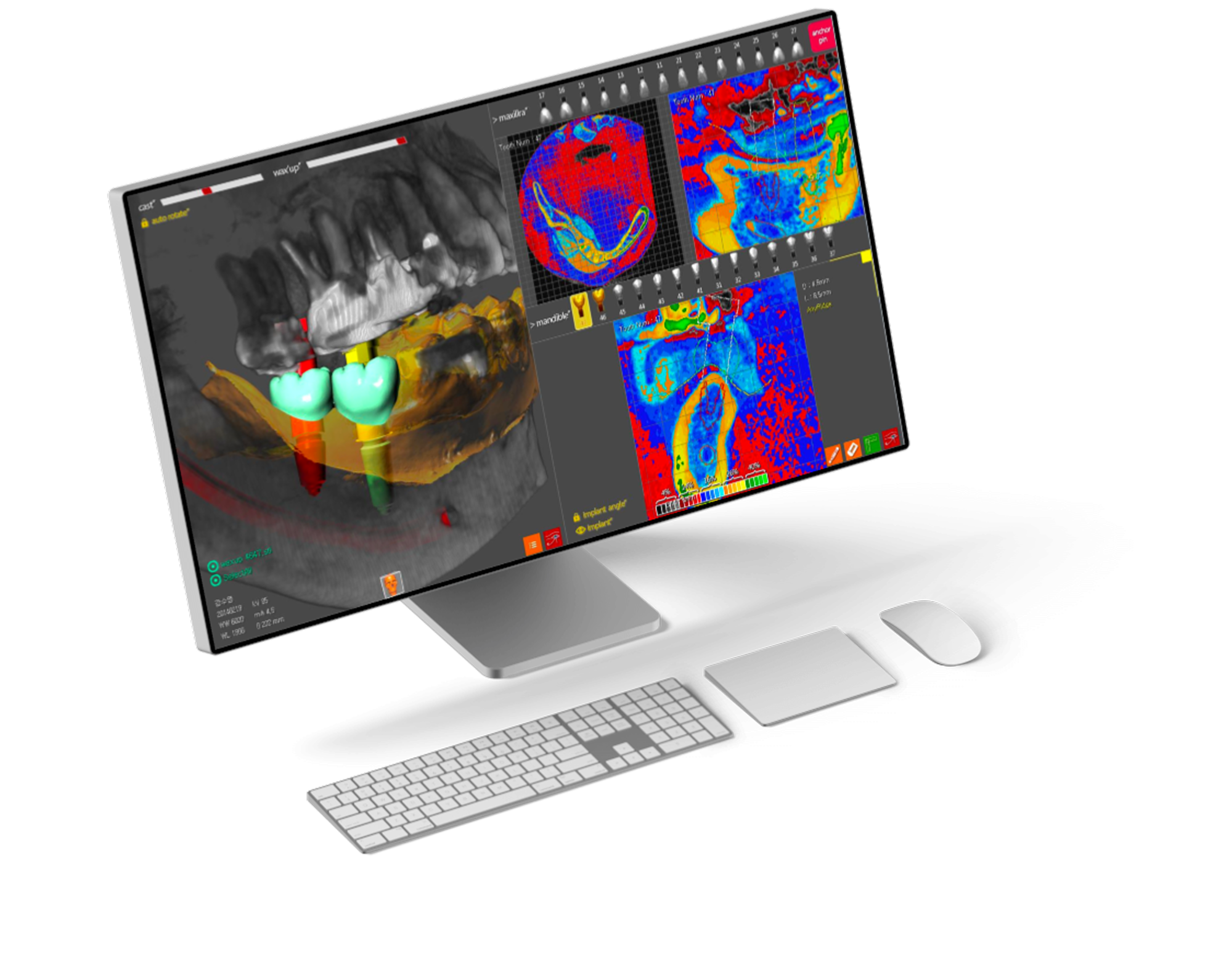

R2Gate official partner

R2Gate enables precise and predictable digital implant planning by combining 3D diagnostics with virtual surgical tools. As your R2Gate official partner, we ensure seamless integration of this cutting-edge technology for safer, faster, and more accurate treatment outcomes.